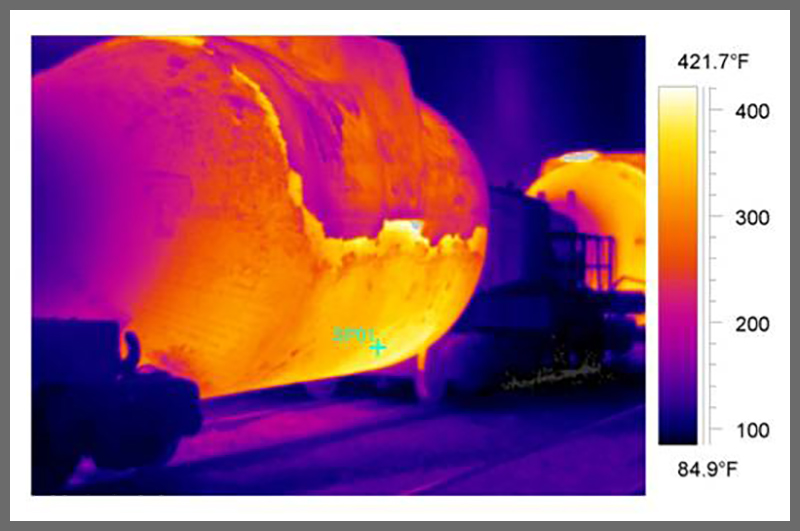

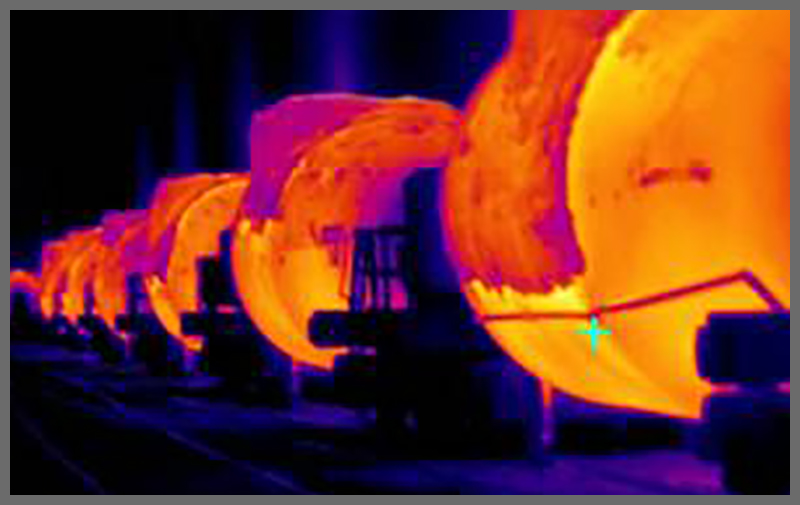

Liquid iron is transported around integrated mills in rail car ladles known as “Torpedo Cars.” The cars are shuttled to different facilities in the plant, and in some instances, to other steel mills completely. To ensure the safety of personnel and the integrity of the vessels, the torpedo cars are scanned by a thermal imager after being filled.

In 2005, Connors Industrials adapted its proprietary AOD Vision™ software (developed for the Argon Oxygen Decarburization process in the stainless steel industry) to create Torpedo Car Vision™. The system utilizes multiple thermal imagers housed in extreme environment enclosures to scan rolling stock on the move. The system scans at several hundred frames per second, so there is no need to slow the operation of the locomotive.

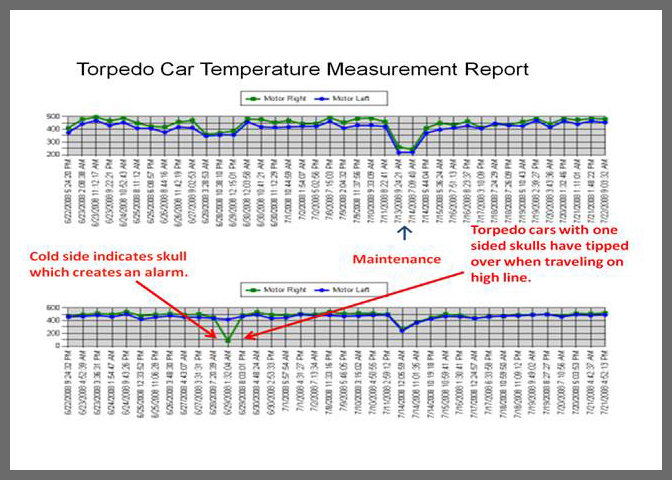

The system allows operators to identify trends in the refractory wear patterns of the Torpedo Cars and thereby make more informed decisions regarding maintenance and operation. The system can even inform operators of a dangerous condition known as a “Bottom or Side Skull”, which occurs when a build up is frozen inside the torpedo. Such a condition is difficult to identify, and can cause major problems such as derail or even a spill when rotating the ladle to pour out its contents. The system alerts the operators of any such irregularities or hot spots, and necessary procedures can be followed to ensure the safety of personnel and protection of equipment.

Torpedo Car Vision™ is another example of how Connors Industrials works with its customers to find solutions to even the most challenging problems. It allows operators to MEASURE the process so that they may CONTROL the process.