Increase Safety & Predict Maintenance: LadleVision® Thermal Imaging System for Steel or Iron Ladles

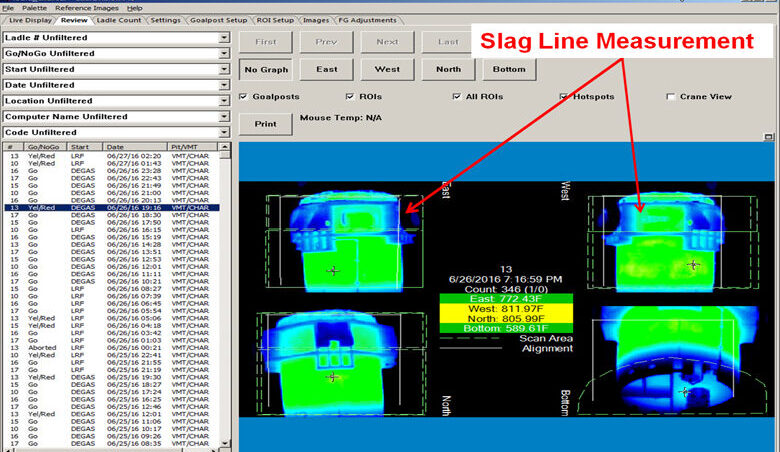

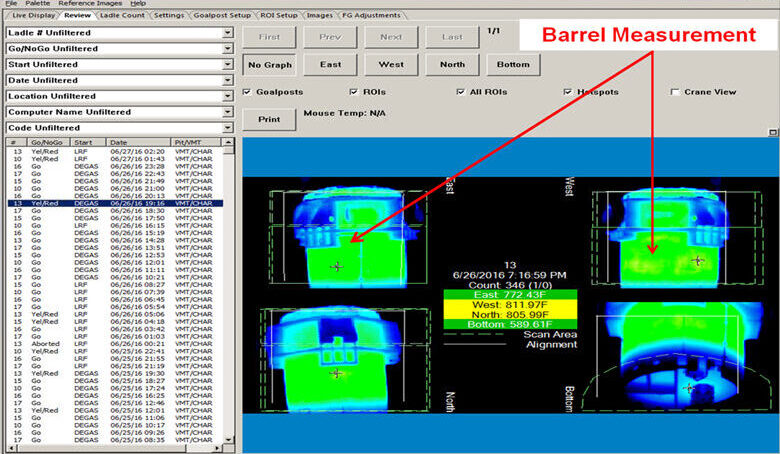

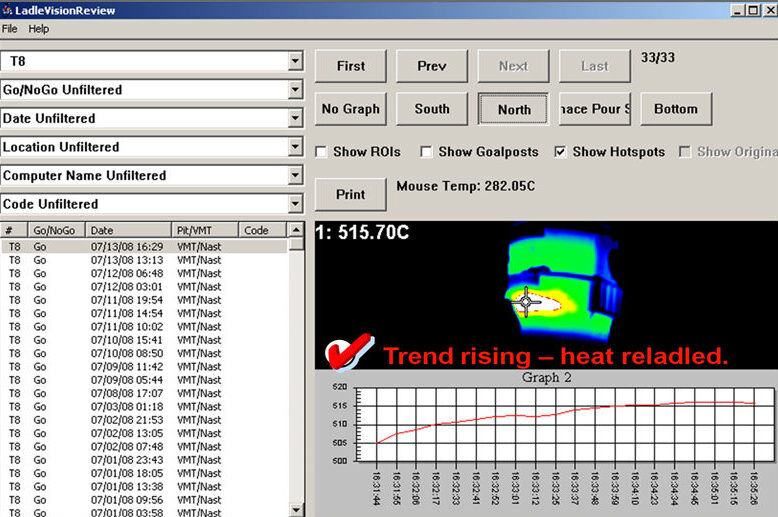

The LadleVision® system consists of networked fixed thermal cameras housed in extreme environment enclosures and a PC server with Connors Industrials LadleVision® software. This automated thermographic solution allows for real-time nondestructive testing or monitoring of transfer ladles.

This automated thermographic solution allows for real-time nondestructive testing or monitoring of transfer ladles.

Benefits

The LadleVision® system increases personnel safety, prevents damage to the equipment and enables the temperature trend analysis necessary to predict maintenance. In this particular application by a major integrated steelmaker, the benefits are:

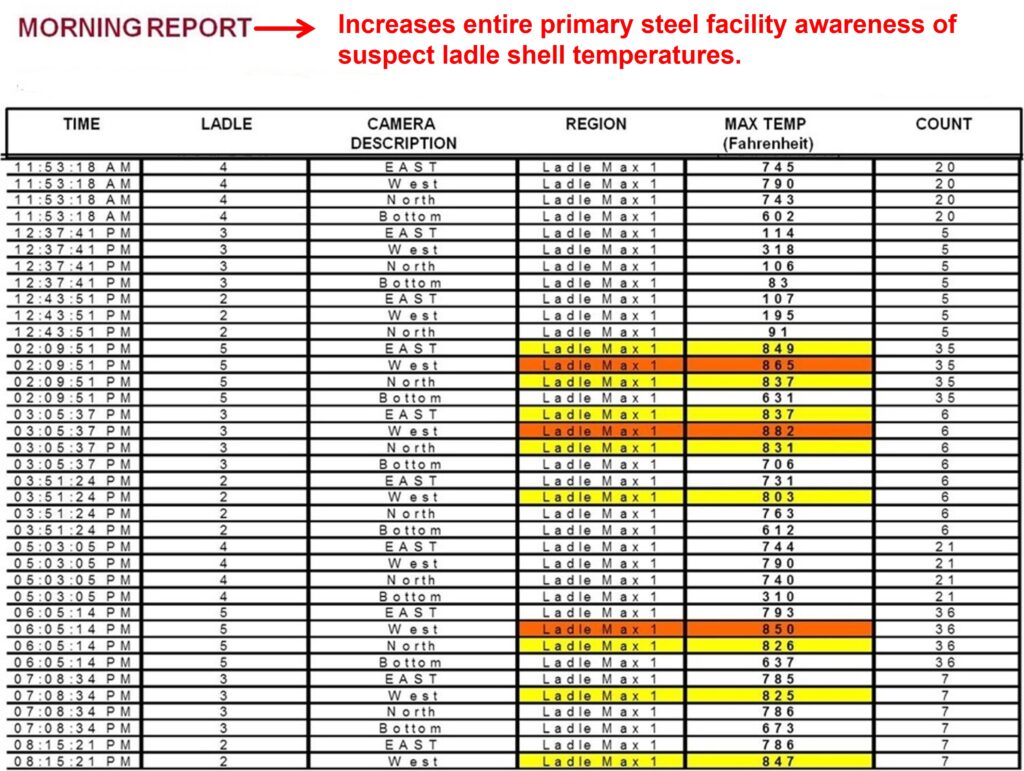

- Improved safety. Fewer failures have occurred during the combined eight years of LadleVision® operations than in the one year before system start-up. Real-time alarms (audio, visual, networked, distributed and email alert) support Operations awareness of ladle vessel temperature status. In-house internet alarms of conditions can be immediately sent to appropriate management.

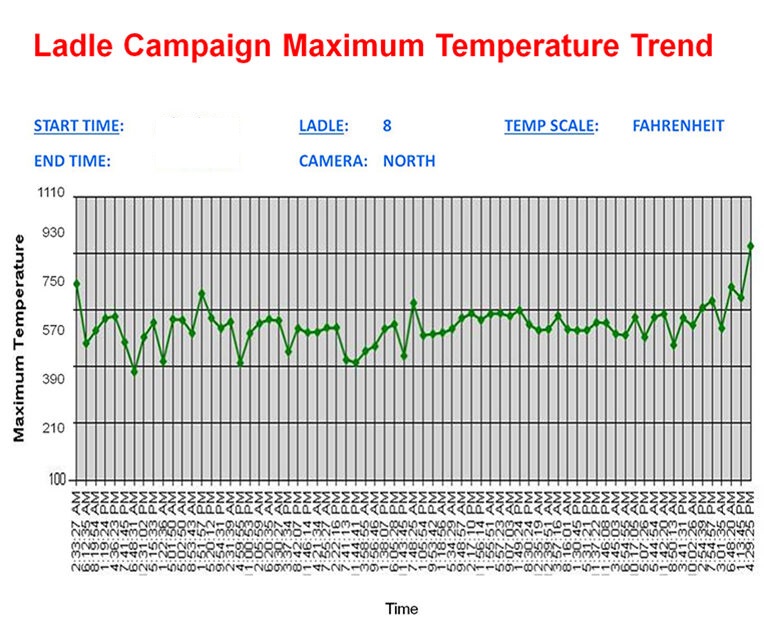

- Predictable maintenance. LadleVision® enables gathering the temperature trend analysis necessary to predict maintenance. This system allows the steelmaker an opportunity to evaluate various refractory substrate performance and heat transfer.

- Reduced operating costs. The capital expenditure for the LadleVision® system has a return on investment in 12-14 months. This automated system continues to give significant operational cost savings.

This large steelmaker has been operating the Connors Industrials LadleVision® System for more than 19 years. The benefits and reliability of the system have resulted in additional installations at locations around the world.

The LadleVision® system has been so successful in supporting safety and refractory management, steel corporations have implemented it at multiple steelmaking facilities with over 80 systems running.

One stainless facility reported the reliability and accuracy of this system extended ladle life by more than 12%.

Over 280 Thermographic Sensor Solutions in Operation

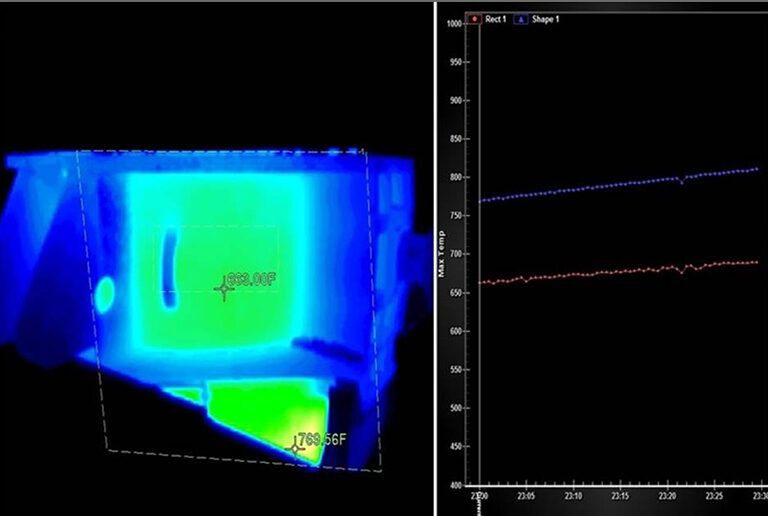

Continuous temperature measurements of ladle shell at secondary processing can measure the kinetic effects of power from

electrodes, stirring from argon plugs and exothermic chemistry changes.