Integrated Thermographic solutions

The incredible value of infrared thermography is that it allows facility managers and staff to see critical equipment concerns before they turn into serious problems. Doing so helps a company to avoid serious safety risks, costly mistakes, and loss of capital equipment. Hot processes with kinetic reactions are extremely difficult to monitor with conventional techniques. However, without monitoring, processes can become out of conformance quickly. With a 24/7 automated infrared thermography approach, the sensor can see beyond visible conditions and monitor risks in real-time as processes continue to operate without interruption.

Our Systems

The Visual Advantage

Reading and data interpretation can be complicated to respond to unless one is extensively trained to know what to look for in the data and respond quickly. That takes months and even years to get someone trained up to the level of instant reaction with such output. With an infrared thermography view, however, people can visually see in the non-visible spectrum of IR what’s deviating from norms literally with their eyes and the color spectrum. The amount of information and signals conveyed are significant and people are able to react with the same level of dedication and response with far less training and the same amount of safety results. Alarms or outputs for machine vision can support operator’s action for safety or clean steel practice. Long story short, infrared thermography monitoring makes a whole lot more sense to people faster than what has been used for traditional heat monitoring.

An Investment That Keeps Paying for Itself

The amount of money spent on an industrial mistake can easily be significant. Given the microscopic cost of an infrared thermography system in comparison, avoiding a high-risk situation makes common sense. Unfortunately, because the disaster hasn’t occurred yet, people oftentimes focus on the cost of the service. It needs to be put into context and evaluated for what the cost avoidance is every time the services find a problem that is corrected early and for minimal expense. Then, the real value of infrared thermography becomes vividly apparent, and the monitoring more than pays for itself many times over.

What to Expect with an Infrared Thermography System?

Every piece of equipment in a system process, manufacturing assembly, heat processing unit, and similar generates a level of heat. Once a baseline image is produced, it becomes very easy for staff to monitor and train to what is the expected norm in operation versus variances and deviations. The eye and visual representation can catch far more detail and process it faster than alpha-numeric readout processing. With camera monitoring instead, folks are able to see minute changes and problem signals before they become something bigger with extended durations. The same can be applied in recordings as well, providing instant training material for other staff to see, realize and learn what is expected operational norms and what should signal a warning or process stoppage to protect the company on the floor.

Types of issues infrared thermography can spot visually include:

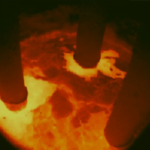

- Reduce slag carry-over from furnace to ladle minimizing time to treat the reducible oxides at secondary processing and improve clean steel processes.

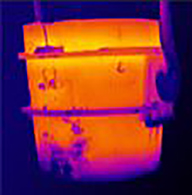

- Observe temperature of critical equipment holding or transporting liquid metals

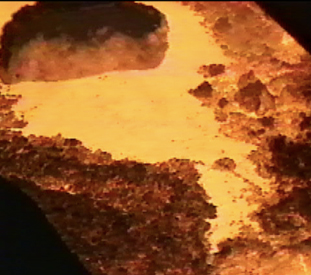

- View inside chamber of LMF for size and position of argon stir, slag surface condition during cleansing rinse, cored wire delivery and costly alloy placement.

- View inside Vacuum Tank Degasser hoods for volatile reactions or measure the rate of rise to auto connect to argon purge and minimize “boil-overs”.

- View inside steel coating line snouts for loss of tension on steel strip, cleanliness of liquid coating bath, pump placement and action if used.

- Support “no operator on the floor” with a remote and customized inspection of electric furnace burners, refractory conditions, and water leaks of water-cooled panels.

- Bearing assemblies that are beginning to fail

- Steam, hot gas, or liquid leaks

All of these issues and many others release heat signatures which can be captured and identified, especially with an infrared spectrum. And that includes issues that may not be apparent to the naked eye but are just as problematic.

Don’t take chances with your people, capital equipment, and resources. Finding the problems before they become a major headache, Connors Industrials can help with our Infrared Thermography Systems. Call us at (219)838-7200 to find out more!

What Makes Connors a Success?

Our people! Over 100 years of steel making experience combined with multiple academic disciplines (Mechanical Engineer, Ceramic Engineer, Electrical Engineer Technician, Thermographers and Computer Science Software Developers) has allowed us to provide customized, turn key thermographic, and inspection monitoring systems to steel and other major industrial manufacturing customers from around the world.

“During the first seven months … before the thermal slag detection system was installed, our conformance standard for phosphorus suffered by 5.6 percent.

After the camera was installed, that percentage was reduced to only .83 percent on those same grades of steel with the same starting turndown phos level.

The ability to consistently control the amount of slag increases the chance of obtaining our phos range on these critical grades.”

What Makes Connors Unique?

Our Service! We don’t just design a system, install it, then walk away. We include a one year warranty, and offer maintenance service contracts, VPN off-site monitoring, 24/7 technical service, on-site training, software updates and reporting options to ensure your investment is reliable and adaptable over time. We’re very proud that every infrared camera system serviced since 1998 is still in operation today.