Introduction

A good number of industrial camera vendors focus on just moving equipment. They provide packaging, equipment modules, and peripherals. However, when it comes to software development to support operational features as well as installation, guidance and education, the critical elements are missing. Connors Industrials took a different approach, focusing on a holistic offering combined with the high performance of FLIR Systems and Valmet sensors equipment. The result has produced a portfolio of thermal imaging system packages that are integrated with client networks to their specifications, match the environments these companies work with, and produce the desired monitoring results needed for enhanced thermal management and decision-making.

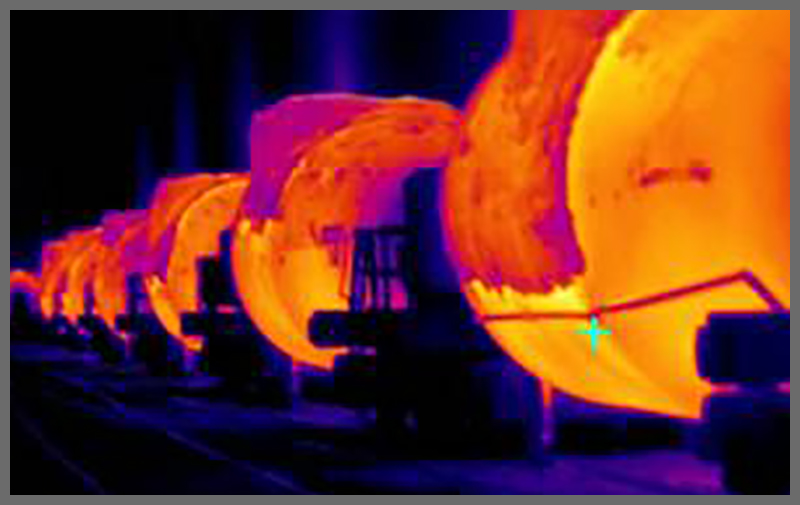

Connors Industrials has been at the forefront of industrial thermal technology creating immensely useful products such as the Thermal Slag Detection™ system, Ladle Vision®-type systems and more in well over 133 facilities. Operating with infrared since the 1990s, Connors Industrials aggregated experience in thermal imaging know-how can’t be beat, nor can it be replicated elsewhere in the market. No surprise, demand clients keep returning to Connors Industrial for guidance, upgrades and new imaging products as a result.

Benefits

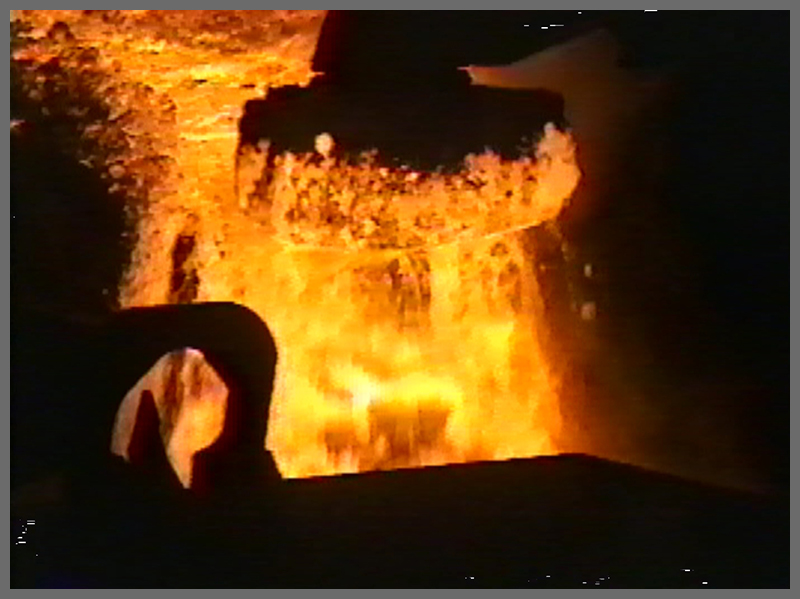

Testing or monitoring that allows product creation or manufacturing to occur without destruction or negative impact is a huge plus. Being able to see temperature in the immediate furnace/ladle environments allows companies to keep production happening at optimum levels as well as spot weaknesses occurring in real time conditions versus lesser ones.

Personnel safety is enhanced with automated and remote camera views, allowing plant operations managers to see intense equipment conditions without having to get close and risking serious injury in the process. Being able to see equipment weaknesses continuously versus periodic checks also spots potential failures before they become a crisis, saving millions of dollars in valuable equipment as well.

Life-usage monitoring provides enhanced evaluation of materials and capital equipment over time. Infrared detailed views and perspectives regarding the strain on equipment and when it has reached its visible end of life. This information has a direct impact on long-term plant investment and technical capital expenditures.

Automation and computerized data capture reduces data collection errors and allows for 24/7 operations versus being restricted to when people are available and on shift.

System Objectives

The goal and technical strategy of a Connors Industrials system has been and continues to be both in-the-moment and trend analysis of what is being observed, particularly from multiple aspects of view, temperature, change in condition, and thermal impacts. By combining all of these elements in a protected manner that can withstand the challenge of the operating environment, Connors Industrials systems are able to place a “camera” in the heat of the operation without the risks and dangers as well. The information gained is exponentially advantageous to operating managers.

Thermal imaging also provides added insight into environments that previously were limited under normal sight camera vision. No matter how high the quality of the lens, it could not penetrate without light. However, in a thermal image view, environments such as total darkness, fog, smoke and haze can be penetrated based on heat signature and temperature differences. The results can be as detailed as seeing the same conditions under clear and unobscured light in many situations.

Application History

Unlike the modern myth that thermal imaging was a result of advancing firefighting technology, the truth of the matter is owned by a far more obvious source, the military. During the Korean War, thermal imaging was developed for rudimentary reconnaissance, scouting and finding the enemy. As it was developed and enhanced, thermal imaging graduated to civilian uses, which include electrical system maintenance, plumbing monitoring and problem detection, facility construction, border control and wildlife management in the field, boat transportation navigation in dark waters, sea life harvesting, firefighting as mentioned earlier, and in recent years, public health protection.

Industrial Evolution with Insight

There’s no question that thermal imaging can be matched with numerous production and facility activities today, and Connors Industrials is available to help bring the greatest benefits from implementing an infrared monitoring system. Call us for a more detailed perspective of how thermal imaging can be applied in your operations. You won’t be disappointed by the insights.

xxxxxxx